History

1945

Founded by Johann Sampl

Johann Sampl, the great-grandfather of the current managing director Hugo Sampl, was a trained manufacturer of watches. In 1945, after the war, the demand for spiral springs for moving-coil movements used in the reconstruction of power plants was very high. Therefore, he founded the spring production in the neighboring town of Mariazell in Rasing, which emerged from his watchmaking business. The machines and tools for the production of spiral springs were designed and built by Johann Sampl himself. Later, the first springs for the electrical industry were also made by hand from round wire.

1975

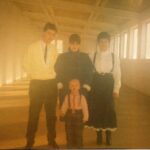

Takeover by Ing. Hugo Sampl sen.

In 1975 his grandson Hugo Sampl senior took over the company with his wife Irmtraud Sampl and developed it further. He developed and built the first universal automatic springs, with which the first large series of springs could then be manufactured.

1980

In the 80s

In the 1980s the products were all made by hand, with the help of all family and friends. During the day, Irmtraud Sampl drived through Mariazell to collect old boxes from the shoe shops and grocery stores so that the finished products could then be delivered using these boxes.

1987

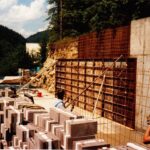

Extension in Rasing

In 1987, a production hall was built next to the residential building, where the spring production was situated.

1991

Move to Gusswerk

In 1991 the company moved to a new, larger 700 m² hall in Gußwerk. In the same year, the current managing director and son of Hugo Sampl sen., Hugo Sampl jun. joined the business.

1994

First electronically controlled spring machine

In 1994 the first electronically controlled spring machine was developed. There was a cooperation with an Austrian electronics manufacturer, which supplied the electronics and control parts of the machines. Due to the size of the company and the large series production, investments were made in the introduction of a quality management system and the certification of the company according to ISO 9001.

1996

Takeover by Ing. Hugo Sampl jun.

In 1996, the 3rd generation Ing. Hugo Sampl jun. took over the family business.

1998

Opening of a subsidiary in Slovenia

In 1998 a second location was opened in Slovenia. With the purchase of a 600m² production hall, from now on mainly hand made products and series productions were made in the neighboring country.

2000

Extension by a 2000m² hall

At the turn of the century in 2000, a new 2000 m² production hall was built next to the existing hall and was officially opened in Gußwerk.

2004

Reorganization into a GmbH

In 2004 the former Ing. Hugo Sampl GmbH & Co KG was reorganized into a pure GmbH.

2014

Big remodel

Due to the growing size of the company, the office building was moved to a separate building and the old hall was modified.

2015

World of Experience Economy

The previous modifications also made it possiblefor visitors, interested parties and school classes to have a sight behind the scenes of the company. By joining the “Experience Economy” project, visitors from then on can visit the company during ongoing operations.

2018

Closure of subsidiary in Slovenia

Economic changes and the realignment of the company led to the closure of the subsidiary in Slovenia in 2018. The subsidiary furthermore could not support the changes ongoing in the company.

2019

New challenges

The constant further development of the company and the focus on the increased production of products for aviation industry led to the company being certified according to EN 9100 in 2019.

2021

Founding of Spring Components GmbH

In 2021, our long-time employee and now friend Roland Harrer and Hugo Sampl jun. together founded a new company – the Spring Components GmbH. With the introduction of new technologies over the years, it has become possible to also act as a component manufacturer. The passion of the two founders for aviation as well as the always future-oriented orientation should reflect the name “Spring Components”.

2022

New focus on aviation

Under the joint management of Ing. Hugo Sampl jun. and DI (FH) Roland Harrer, not only springs and bent parts are developed, designed, produced and supplied with self-constructed, self-built, electronically controlled spring coiling machines and state-of-the-art spring coiling centers, but also entire components for aviation industry are produced by most modern CNC centers and electrical discharge machining technology.

2024

Since 2023, Spring Components GmbH has been managed by Hugo Sampl as sole Chief Executive Officer. In economically challenging times, our company deliberately invested in expanding its toolmaking operations and modernizing its machinery to sustainably strengthen its competitiveness and vertical integration.